Last October we published the following technical paper in the INDUSTRIA QUÍMICA magazine: SOLUTION OF THE CORROSION PROBLEMS OF A HIGH PRESSURE WATER-STEAM CYCLE IN A HEAVY CHEMICAL INDUSTRY. CASE OF SUCCESS WITH ADICONTROL TECHNOLOGY.

Based on the recommendations made by the EPRI (Electric Power Research Institute) and IAPWS (International Association for the Properties of Water and Steam) organisations for high pressure water-steam cycles, Adiquimica presented in this publication its Adicontrol technology, which provides effective corrosion protection for the metal surfaces of the entire high pressure water-steam cycle.

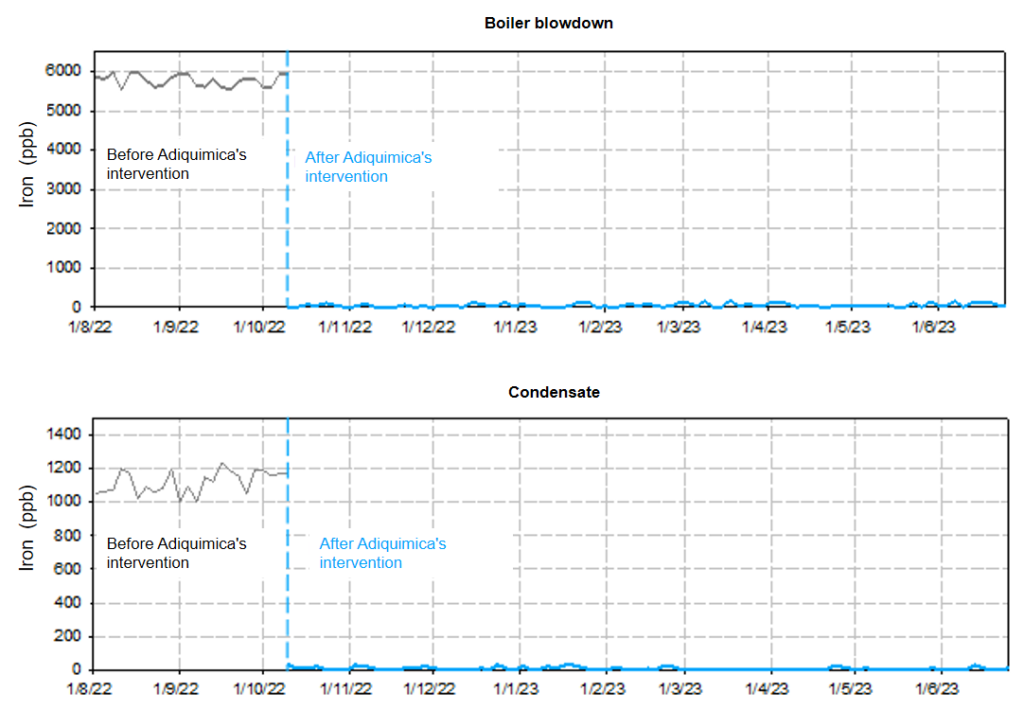

In this work we present the specific case of an episode of corrosion under deposit in the heat exchangers of a chemical industry plant. In this case, a diagnosis of the client’s problem was carried out, an appropriate technical solution was studied and designed for its resolution, and finally, the results obtained in the monitoring of the operation of the installation, after a treatment period of more than nine months, are presented in order to confirm the suitability of the solution implemented.

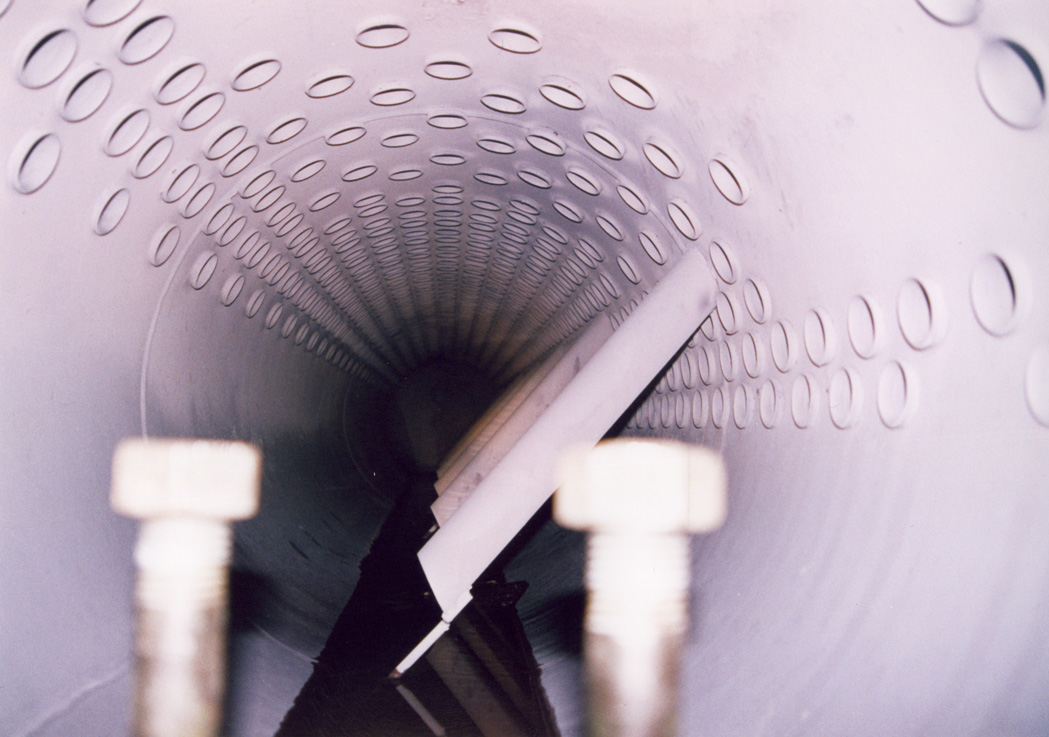

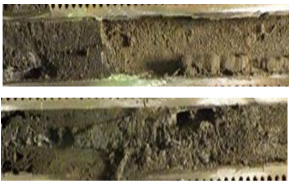

Before ADIQUIMICA’s intervention, one of the exchangers of the client’s installation showed clogging and deformation of its tubes. The following problems occurred in the water-steam cycle that forced additional production stoppages to those scheduled with their associated costs, both in terms of materials to be replaced and temporary cessation of production activity.

- Corrosion under deposit in the heat exchanger tubes.

- High accumulation of deposits on the inlet manifold and heat exchanger tubes.

The implementation of an optimised chemical treatment and the ADICONTROL technology achieve an integral control of the high pressure water-steam cycle, allowing operation in accordance with the recommendations of the EPRI (Electric Power Research Institute) and IAPWS (International Association for the Properties of Water and Steam) organisations, in relevant parameters such as pH and conductivity, avoiding corrective interventions and minimising operating costs. The chemical treatment based on oxygen reducer, volatile alkalising and alkalising of the generator water, achieves effective corrosion protection of the metal surfaces of the entire high-pressure water-steam cycle.

ADICONTROL technology monitors system conditions and water-steam cycle performance in real time, improves process performance, controls corrosion, keeps surfaces clean, and reduces water and energy consumption.

The results enable sustainability goals to be met with continuous steam production and system protection, reducing operating costs and CO2 emissions.

To access the full article click here