services

Advantages

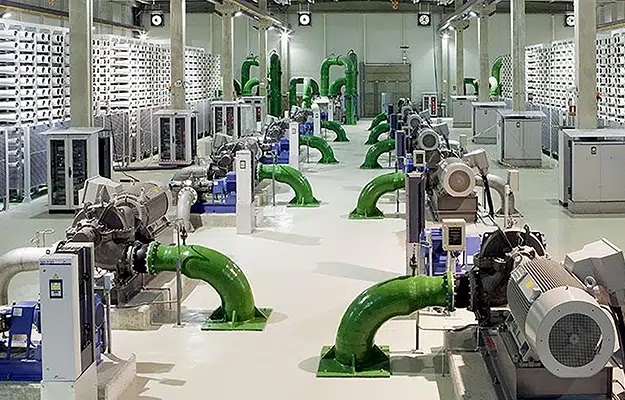

We are specialists in water treatment for reverse osmosis, nanofiltration (NF), ultrafiltration (UF) and reversible electrodialysis (EDR) installations.

We reduce the operating costs of your plant by applying the best treatment to maintain adequate water quality, guaranteeing optimal performance of the facilities.

How do we work?

We carry out a personalized study of the inlet water to your facilities to anticipate the risks of fouling that may arise in the membranes.

We design the optimal treatment so that your plant has the best performance and we guarantee a significant cost reduction.

In support of water treatment, we perform membrane autopsies to determine the exact causes of fouling.

We design cleaning tests to select the most appropriate treatment and the optimal doses of chemical products.

Innovation

We use the most advanced analysis techniques, which provide us with an accurate diagnosis of what is happening in the system.

Deposit light microscopy

Scanning electron microscopy studies

Analysis by energy dispersive X-rays (SEM-EDX)

Fourier Transform Infrared Analysis (FTIR-ATR)

Follow up

We monitor the operating parameters of the reverse osmosis plant before and after each cleaning. Thus, we optimize the cleaning protocol and select the most suitable products to eliminate the dirt detected.

Software

We have developed a unique and specialized monitoring software that adapts to the new market demands.

A scientific software tool that provides a highly accurate prediction of scale formation and calculates the proper dosage of antiscalant.

With this software, it is possible to simulate and calculate the ionic species in reverse osmosis installations and determine the minimum dose of inhibitor necessary to keep the limits of supersaturation and fouling under control.

It is a simulation system for chemical cleaning in reverse osmosis plants. It can develop custom cleaning protocols for each facility, allowing for more efficient and effective cleaning of membranes.

With AdiClean you can simulate different fouling scenarios and determine the most appropriate cleaning protocol, which reduces cleaning time and cost and increases the useful life of the membranes.

Adic is a tool designed to monitor and control the main operating parameters of a facility.. It has a database where all the analyzes carried out are stored and offers graphic tools to analyze the evolution of the measured parameters and predict trends.

Equipment

We work with equipment designed and developed by our R+D+i department.

Adicontrol® is a device specialized in the control, management and supervision of the implementation of chemical treatments.

This equipment allows you to monitor the main operating parameters in refrigeration or steam generation circuits, such as pH, conductivity, free chlorine, redox potential and level of antifouling active ingredient.

All this is integrated into a management module governed by ADIC, generating trend graphs, and calculating deviations and key process indicators (KPI).

It is a portable system for measuring the anti-scaling active principle in reverse osmosis installations that use the products of our ADICRO range. This system allows a precise and easy measurement of the active principle at any time and in any place of the installation.

For the implementation of any chemical treatment, it is necessary to have dosing pumps. . These pumps can be governed by equipment from the Adiconline and Adicontrol range, which allows their integration into the control laws defined for the implementation of treatments.

SERVICES

Discover our additional services that might interest you. At Adiquímica, we are not only leaders in

industrial water treatment, but we also offer a wide range of strong, complementary solutions

to cover all your needs.

SERVICES

Lorem fistrum por la gloria de mi madre esse jarl aliqua llevame al sircoo.

SERVICES

Lorem fistrum por la gloria de mi madre esse jarl aliqua llevame al sircoo.

SERVICES

Lorem fistrum por la gloria de mi madre esse jarl aliqua llevame al sircoo.

certifications

Blog

Stay up to date on industry news and new regulations that may affect your company

Contact

To provide the best experiences, we use technologies such as cookies to store and/or access information on your device. Consenting to these technologies will allow us to process data such as browsing behaviour or unique identifiers on this site. Not consenting, or withdrawing consent, may adversely affect certain features and functions.